Why Kothari

- Why Kothari

About German

Thermex Technology

Our KOTHARI TMT Bars, produced using German Thermex Technology (TMX), are of superior quality due to their high tensile strength compared to conventional options. The German Thermex thermo-processing treatment enables the production of exceptionally strong rebars with a yield strength ranging from 550 N/mm² and above. This process enhances robustness, flexibility, weldability, and yieldability.

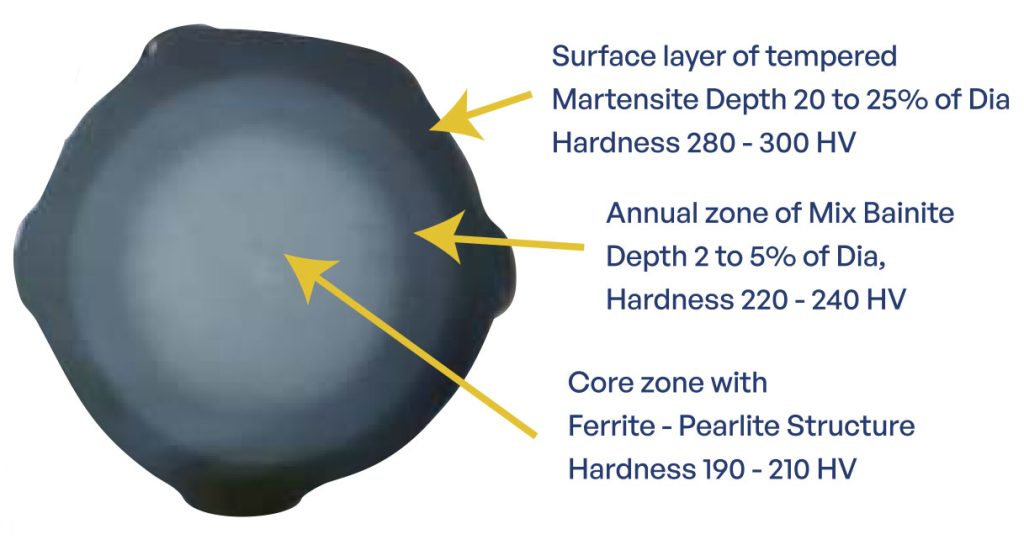

The German Thermex Technology involves a brief but precise in-line cooling of the rolled bar, resulting in a hardened outer layer. Subsequent cooling facilitates thermal exchange (THERMEX) between the inner and outer surfaces of the bar. This process creates a distinct tempered martensite layer on the outer surface and a fine-grained ferrite-pearlite structure in the core, ensuring optimal performance and durability.

German Thermex Technology

Our KOTHARI TMT Bars, produced using German Thermex Technology (TMX), are of superior quality due to their high tensile strength compared to conventional options. The German Thermex thermo-processing treatment enables the production of exceptionally strong rebars with a yield strength ranging from 550 N/mm² and above. This process enhances robustness, flexibility, weldability, and yieldability.

The German Thermex Technology involves a brief but precise in-line cooling of the rolled bar, resulting in a hardened outer layer. Subsequent cooling facilitates thermal exchange (THERMEX) between the inner and outer surfaces of the bar. This process creates a distinct tempered martensite layer on the outer surface and a fine-grained ferrite-pearlite structure in the core, ensuring optimal performance and durability.

The German Thermex Technology involves a brief but precise in-line cooling of the rolled bar, resulting in a hardened outer layer. Subsequent cooling facilitates thermal exchange (THERMEX) between the inner and outer surfaces of the bar. This process creates a distinct tempered martensite layer on the outer surface and a fine-grained ferrite-pearlite structure in the core, ensuring optimal performance and durability.

German Thermex TMT Reinforced Bars

The patented Thermex cooling technology has significantly benefited the Civil Industry by reducing costs and contributing to the global economy. Here are several reasons why Thermex technology TMT bars are highly preferred and widely accepted:

- Superior quality at a lower price, saving up to 17%

- High strength and ductility suitable for all types of construction

- Excellent corrosion resistance

- Greater fire resistance compared to regular TMT bars

- Enhanced fatigue resistance and easy weldability

- Improved earthquake resistance due to high ductility

Finished Goods

The billets are maintained at a controlled temperature to ensure the desired quality of the final product. Our in-house Rolling Mill Laboratory is equipped with a Universal Testing Machine to measure UTS, yield strength, elongation. calibrated weighing scales to determine weight per meter, calibrated vernier calipers determine rod diameter, all in accordance with ISI standards. Only after passing these tests and clearing the lab reports are the TMT Bars approved for delivery and dispatch.

Quality

Quality is our foremost priority, and it naturally reflects in our output. Industry standards serve as our minimum benchmarks. We strive to maintain superior quality, consistently, and better value for money in our products. Our meticulous attention to detail, from raw material procurement to the delivery of finished goods, ensures customer delight.

Melting of Raw Materials

The initial step in processing raw materials involves melting. To ensure the correct chemical composition, samples of the molten metal are tested in the lab using a spectrometer. Required elements are added as necessary until the desired composition is achieved. This step is critical as it directly affects the quality of the final product.

Special Length

Cut to customized length tmt bars can be pre-ordered. Our precision cutting system cuts the bars on the fly enabling lowest wastage and maximixed savings for the customer.

Bridges, long span floors, wind-mills and many other projects prefer special length tmt bars from Kothari for unmatched precision, ease of availability and small ticket size orders.

Kothari Trust

Kothari TMT bars has the best combination of strength and ductility and unparalleled quality consistency. It is available through our professional distribution and dealers’ network, assuring the company prescribed price and correct weight at the point of purchase. This ensures a deep-rooted trust in Kothari TMT bars – one of the core values of the brand.

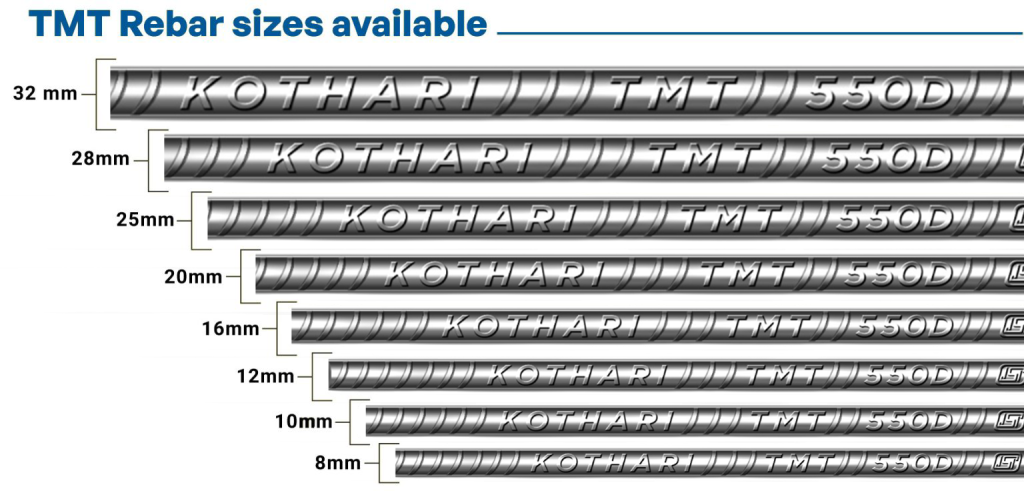

Size range

Kothari TMT Rebars are available in the following sizes as per: 1786-2008 for Concrete Reinforcement.

The rebars are delivered in standard length of 12 Meter bundles ensuring ease in transportation.

| Dia (mm) | Min Weight (kg/mtr) | Nominal Weight (kg/mtr) | Max Weight (kg/mtr) | Length Per Rod (mtr) | Typical Weight Per Rod (kg) |

|---|---|---|---|---|---|

| 8 | 0.367 | 0.395 | 0.423 | 12 | 4.470 |

| 10 | 0.574 | 0.617 | 0.660 | 12 | 7.404 |

| 12 | 0.844 | 0.888 | 0.932 | 12 | 10.657 |

| 16 | 1.449 | 1.578 | 1.657 | 12 | 18.936 |

| 20 | 2.392 | 2.466 | 2.540 | 12 | 29.592 |

| 25 | 3.738 | 3.854 | 3.970 | 12 | 46.248 |

| 32 | 6.121 | 6.310 | 6.499 | 12 | 75.720 |

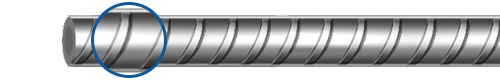

Superior Rib Pattern

Although steel and concrete are two different materials, they to behave as a single unit in a reinforced structure. This can happen only when the concrete grips the steel rebar to form the strongest bond through the unique rib pattern of the rebar. Kothari TMT Bars has unique rib pattern in terms of greater rib depth and closer rib spacing. Its ribs are made using computer controlled CNC notch cutting machines.

Rib patterns on the rebar surface provide quality bonding with cement only when they are produced through CNC machined Rolls.

This ensures uniform rib pattern for 100% of the rebars, which allows uniformly strong bonding with concrete for the whole structure. This is in contrast to the ordinary rebars, where ribs are cut manually which always leaves scope for non-uniform rib pattern and thereby, non-uniform and weaker bonding throughout the structure. Due to uniformity and critically designed ribs, fatigue strength of Kothari TMT Bars is much superior to ordinary rebars.

Rib patterns on the rebar surface can give quality bonding with cement only if they are produced through CNC machined rolls.

Metallurgical Perspective

Steel’s properties can be tailored by adjusting its microstructures, influenced by its chemical composition and thermal treatment. Rebar combines different microstructures, with a hard martensitic outer layer and a softer ferritic-pearlitic core, formed through self-tempering.

This process enhances rebar strength, ductility, and corrosion resistance while improving weldability. Kothari TMT bars, produced using advanced automation and control systems, offer superior tensile strength, thermal stability, and a ribbed design for strong bonding with concrete. These qualities make them safer during natural disasters like earthquakes and more resistant to fire.