Products

- Products

Our Products

Fe 500D

'D' for Ductility

Fe 550D

'D' for Ductility

CRS

(Corrosion Resistant Steel)

Special Length

Chemical & Mechanical Properties

| REBAR GRADE (%) | Kothari Fe500D Typical Values | Kothari Fe550D Typical Values | Kothari CRS Typical Values |

|---|---|---|---|

| Carbon (Max) | 0.25 | 0.20 | 0.25 |

| Silicon | 0.15-0.25 | 0.25 | 0.20-0.30 |

| Manganese | 0.65 - 0.75 | 0.65 - 0.75 | 0.65 - 0.75 |

| Sulphur (MAX) | 0.040 | 0.035 | 0.040 |

| Phosphorus (MAX) | 0.040 | 0.035 | 0.040 |

| Sulphur + Phosphorus (MAX) | 0.075 | 0.070 | 0.075 |

| Carbon Equivalent (CE) MAX | 0.31-0.36 | 0.42 | 0.53 |

| Copper | 0.18 -0.25 | ||

| Chromium | 0.35 - 0.45 | ||

| Yield Stress (N/mm2) MIN | 525 | 580 | 525 |

| Elongation (MIN) | 18 | 18.0 | 16 |

| Ultimate Tensile Strength (N/mm2) MIN | 575 | 680 | 600 |

| UTS/YS Ratio | 1.15 | 1.15 | 1.15 |

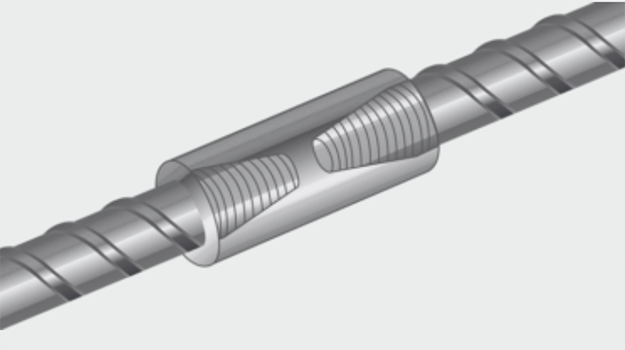

Suitable for using threaded stablecouplers

Kothari TMT bars can withstand high pressure cold forging process and can be forged uniformly to the required length. Our TMT bars can withstand the threading process (both taper and parallel) without generating metal shavings, which may cause harm while joining tow rods with coupler.

Corrosion Resistant

Kothari rebars is produced by TMT technology and not by cold twisting. Therefore, there is no torsional residual stress in the bar, which result in superior corrosion resistant characteristics compared to traditional cold twisted bars. On account of its composite and uniform microstructures, Kothari TMT has comparatively better corrosion resistant properties than other TMT bars, while being embedded inside concrete.

Earthquake Resistant

The buckling effect will occur while applying load to the structure even after deformation, thus become unstable. Such impact load occurs during earthquake, causing the structure to collapse. Our TMT Bars can withstand the buckling effect that occurs due to sudden sideways deflection of structure member.